In the intricate dance of molecules that shapes the materials of our daily lives, polyamides play a leading role. Known for their robustness and versatility, these polymers, particularly Polyamide 6 (PA6) and Polyamide 66 (PA66), stand as titans in the realm of engineering plastics. Yet, despite their prominence, a challenge persists. Distinguishing these molecular siblings in recycling, where their semblance can lead to mix-ups, compromising material integrity.

What is Polyamide (Nylon)?

Polyamides, commonly called nylon, are a type of engineering thermoplastics. Engineering thermoplastics are group of plastics that can be melted and reshaped. This category includes nylons (PA6, PA66), along with other plastics like polyesters (PET, PBT), polycarbonate (PC), polyacetals (POM), and acrylonitrile-butadiene-styrene (ABS). Nylon was discovered by Wallace Hume Carothers in 1935, nylon’s creation was a groundbreaking development in polymer science. Polyamides boast exceptional qualities, including remarkable temperature and electrical resistance, thanks to their crystalline structure. These polymers also exhibit outstanding chemical resistance and are inherently flame retardant. Furthermore, incorporating glass fibers can further enhance their mechanical robustness, positioning them as formidable contenders alongside metals in diverse applications.

In plastic sorting, the purity of the recycled material significantly determines the value of the end product. The presence of even small amounts of a different polymer, such as mixing PA6 with PA66, can drastically alter the material’s properties. Hence, this mix-up can lead to underperformance in applications where specific characteristics like temperature resistance or mechanical strength are crucial. Therefore, the ability to differentiate between these polymers accurately is not just beneficial but essential.

PA6 vs. PA66

Polyamide 6 (PA6)

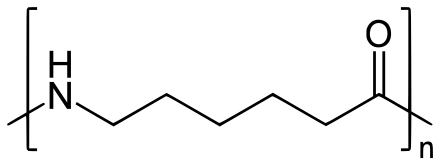

- Also known as nylon 6 or polycaprolactam, PA6 is a versatile and widely used engineering thermoplastic in the polymer industry.

- PA6 is synthesized through a process called ring-opening polymerization of caprolactam, a cyclic amide compound. This process involves breaking the ring structure of caprolactam molecules and connecting them to form long chains. Hence, this results in the formation of PA6 polymer.

- One of the notable properties of PA6 is its moderate melting point, which stands at approximately 223°C. This melting point makes it suitable for various applications that require a balance between thermal resistance and processability.

- PA6 is known for its excellent mechanical properties, including good tensile strength, impact resistance, and abrasion resistance. It also exhibits high chemical resistance and durability, making it suitable for a wide range of applications.

Polyamide 66 (PA66)

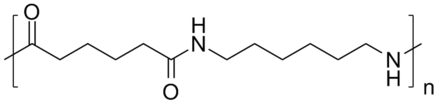

- PA66, often referred to as nylon 66, is another prominent engineering thermoplastic in the polymer industry.

- Polyamide 66 is produced through a process called polycondensation. This process involves the reaction between two monomers: hexamethylene diamine and adipic acid. The reaction leads to the formation of a long-chain polymer with repeating units of amide groups, hence the name “polyamide.”

- PA66 has a higher melting point compared to PA6, with a melting point of approximately 255°C. This higher melting point imparts excellent thermal stability to PA66. Hence, making it suitable for applications where exposure to high temperatures is a concern.

- Polyamide 66 shares some common characteristics with PA6, such as good mechanical properties, chemical resistance, and durability. Nevertheless, PA66 often garners preference in situations necessitating heightened heat resistance due to its superior ability to withstand elevated temperatures.

PA6 and PA66 The Recycling Challenge

Recycling PA6 and PA66 poses a complex challenge primarily due to their widespread use and the similarities in their properties. While these polymers share many characteristics, even minor differences can have significant implications in the waste management process. Some key factors that complicate plastic sorting include moisture absorption capacity, modulus, wear resistance, and heat resistance. When these polymers intermingle during the waste management process, the resultant material may fall short of meeting the necessary performance standards for particular applications, ultimately diminishing its value or rendering it unusable.

Mechanical Recycling

- One of the primary methods for recycling PA6 and PA66 is mechanical recycling, a process that involves several steps:

- Shredding: The first step in mechanical recycling is the shredding of post-consumer or post-industrial plastic waste, including items made from PA6 and PA66. Moreover, this shredding process reduces the plastic material into smaller pieces, often referred to as flakes or granules.

- Melting: After shredding, the plastic flakes are melted down. This involves subjecting the shredded plastic to high temperatures until it reaches a molten state. The melted plastic can then be further processed.

- Extrusion: Extrusion is the next stage, where the molten plastic is forced through a die to create a consistent shape or form. Furthermore, in the case of PA6 and PA66 recycling, this often results in the formation of pellets or similar shapes.

Mixed Plastic sorting Challenges:

One of the significant challenges in recycling PA6 and PA66 lies in the mixing of these two polymers. While they may appear similar, their distinct properties, especially related to moisture absorption, modulus, wear resistance, and heat resistance, can lead to problems when combined. These issues can include compromised material properties in the recycled product, making it less suitable for specific applications that require precise material characteristics.

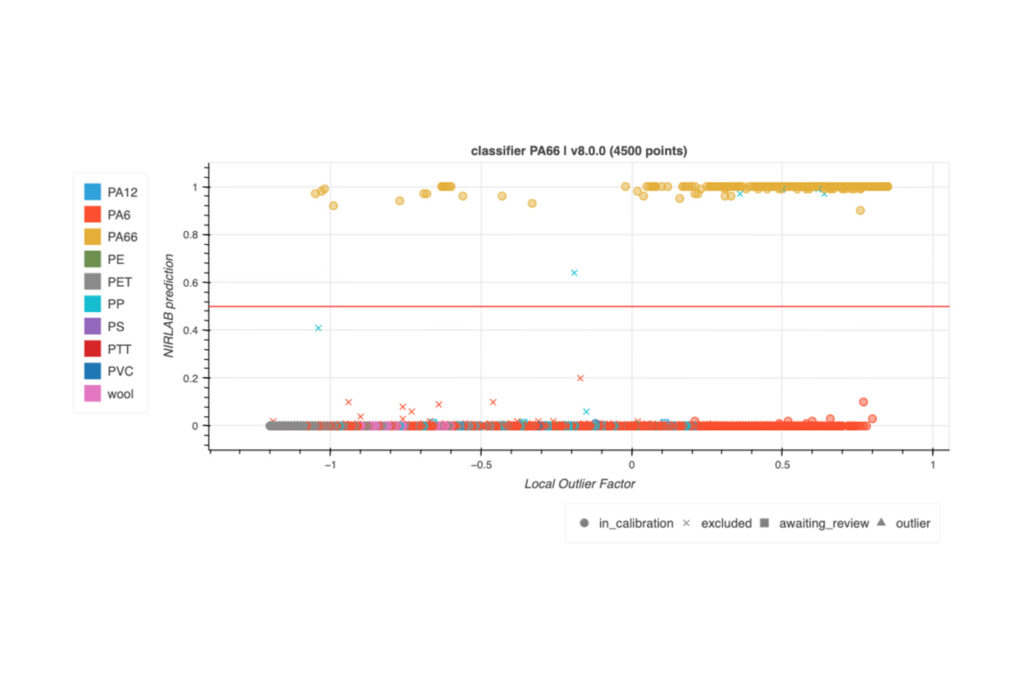

To address these challenges, advanced technologies and methods, such as those offered by NIRLAB, have emerged to enable the accurate differentiation between PA6 and PA66 during the waste management process. This technology ensures that only the desired polymer type is used in recycled products, maintaining the integrity and performance of the materials. This innovation significantly contributes to the efficiency and effectiveness of plastic sorting processes and the sustainability of the polymer industry as a whole.

NIRLAB’s Technological Edge

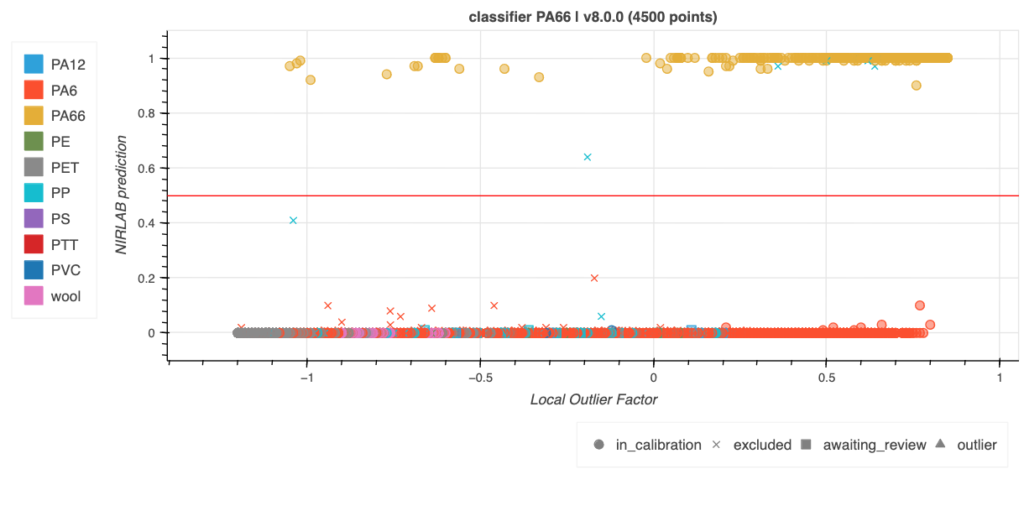

NIRLAB Polymers has addressed this challenge by developing a groundbreaking solution that allows rapid differentiation between PA6 and PA66. In just 5 seconds, our technology accurately distinguishes between these two polymers, eliminating the need for melting and pelletizing. Our solution employs Near-Infrared (NIR) spectroscopy combined with advanced machine learning algorithms to create a robust system for polymer identification. With NIRLAB’s technology, plastic sorting plants can sort polymers with with high accuracy, leading to purer recycled materials. This purity enhances the performance of recycled products. Hence, making them more competitive with their virgin counterparts and increasing their market value. Moreover, it aligns with environmental sustainability goals by reducing waste and improving the efficiency of waste management processes.

To learn more about our polymer solution, we invite you to check our polymer application page, here.

Practical Applications

Our technology finds practical applications across diverse industries:

- Automotive Industry: In automotive manufacturing, where polymers replace metal for weight reduction and cost savings, the use of pure recycled materials is critical. NIRLAB’s technology ensures the use of only the desired polymer type in components, thereby maintaining safety and performance standards.

- Consumer Electronics: In the realm of consumer electronics, characterized by miniature components and paramount functionality, precise polymer identification stands as an essential requirement. Our technology provides the accuracy needed in this high-stakes industry.

- Packaging: In the packaging sector, where material properties like barrier strength and flexibility are key, NIRLAB’s solution ensures that recycled materials meet the strict standards required for food safety and durability.

The Future of Polymer Analysis

As the polymer industry undergoes continuous evolution, NIRLAB remains steadfast in its commitment to leading the way in technological advancements. We reflect our dedication through continuously updating our substance library and refining our algorithms. We drive these efforts to effectively address new polymers and meet emerging market requirements.

In the development of our technology, every sample within our complex algorithm undergoes meticulous manual scrutiny. This hands-on approach ensures the highest level of accuracy and reliability in our models. Our strength lies in our adaptability and flexibility in development, allowing us to craft tailor-made solutions that precisely cater to the unique needs of our clients and the ever-changing polymer landscape.

Throughout the development process, we consider various critical aspects, including color, physical characteristics, grade of washing, and more. These considerations are integral to the creation of the most stable and robust models possible, ensuring the optimal performance and effectiveness of our polymer identification solutions.

Conclusion

In the evolving landscape of materials science, the challenge of distinguishing between Polyamide 6 (PA6) and Polyamide 66 (PA66) transcends a mere technicality; it represents a microcosm of the broader quest for sustainability and efficiency in recycling. These polymers, while superficially identical, embody the nuanced challenges and opportunities in achieving a circular economy. Their differentiation is not just a task but a necessity. This is highlighting the intricate dance between innovation, environmental stewardship, and the practicalities of recycling.

The PA6 and PA66 story highlights polymers’ transformative impact across applications, posing waste management challenges.Given the recycling complexities and property differences, precise materials management is crucial. A reminder of the delicate balance required between technological advancement and ecological responsibility underscores the importance.

Breakthroughs like NIR spectroscopy, coupled with machine learning, revolutionize polymer sorting by swiftly and accurately distinguishing materials. These advancements boost recycled material value and align with environmental goals, promoting resource conservation and waste reduction.

These innovations extend their impact across various industries, ensuring that the purity of recycled materials meets stringent standards, thereby supporting safety, performance, and sustainability. As technology evolves to meet new challenges, it underscores a commitment to continuous innovation, reflecting our collective determination to navigate the complexities of sustainability with ingenuity.

In summary, the journey of PA6 and PA66 from problem to solution encapsulates a broader narrative of human ingenuity confronting environmental challenges. It underscores the potential for technological innovation to drive us toward a more sustainable, efficient, and responsible future, reinforcing the belief that our greatest advancements lie at the intersection of environmental stewardship and innovative problem-solving.

To explore more about spectroscopy and discover the full capabilities of NIRLAB’s technology, we invite you to read our other informative articles, here. For personalized inquiries, please don’t hesitate to reach out to us at contact@nirlab.com.

NIRLAB // Just Truth