Recycling has become an important subject in today’s society due to the impact of waste on our environment and the loss of valuable resources. Whereas in the past, recyclable materials (e.g. paper, plastics, and textiles) were sorted mainly by hand, the use of near-infrared (NIR) spectroscopy has become a standard in the recycling industry.

One of the most difficult materials to classify in recycling waste streams is plastic. The primary methods to distinguish between plastics are time consuming and are prone to errors due to an inaccurate sampling.

Other methods are relate to hyperspectral imaging that is really expensive and requires an advanced knowledge of Machine Learning.

Our approach

Reflection measurements employing near-infrared spectroscopy enable the classification of many of the most common polymers present in recycling waste streams. Each polymer has a distinctive fingerprint spectra which allows for the identification of recyclable plastics and the elimination of contaminants, which can create downstream problems in the plastic extrusion process.

Nevertheless, there are several topics that are making this application challenging:

- Colour

- Dirtiness

- Various shapes

- Various thickness

- Very similar spectra for not so similar polymers

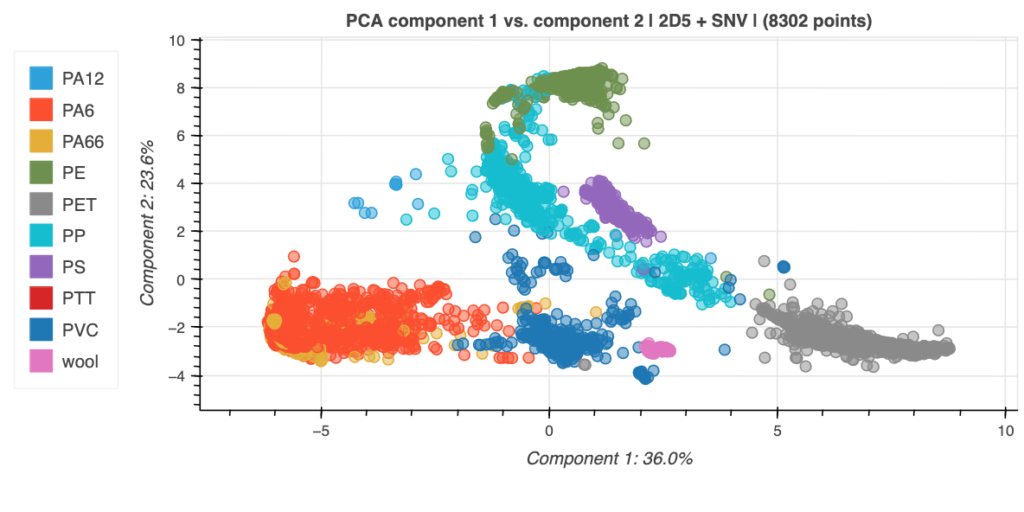

The following is a picture of a subslicing of the data collection, as expected different polymers are not related to each other (e.g. PA12 and PET) but there are also some clear overlapping zones (e.g. PE and PP) and total overlapping zones (PA6 and PA66)

Plot of the first two components of the PCA made on a subslice of our dataset

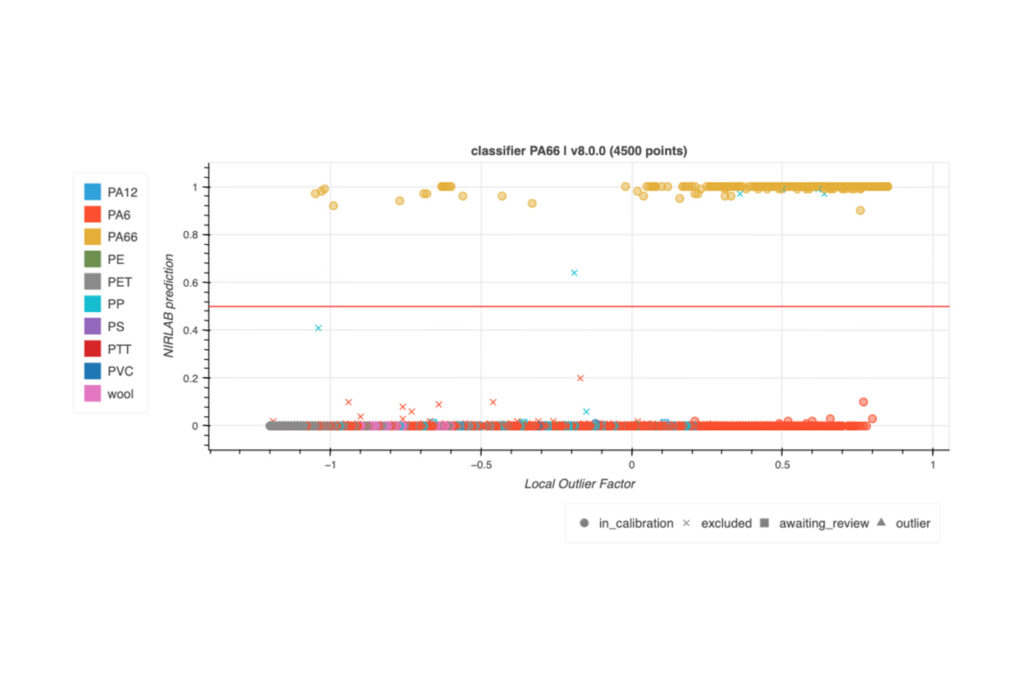

To solve this complicated issue we developed a refined logic where we combine multiple classifiers for every substance while a special SMV is supervising all the work. We are capable to identify several polymers (PBT, PA, ABS, etc.) considering also color, for some some of them we have developed very specific models (PA6 vs PA12, HDPE vs LDPE), for other we have developed dedicated submodels (cellulose-acetate, cellulose-acetate-butyrate, cellulose-acetate-propionate).

Our system is also extremely flexible and adding more polymers is really easy and fast and fully automatized: we do not require highly specialised staff since all chemometrics is automatic ore done by us.