In our modern world, the issue of plastic recycling has evolved into a global environmental crisis, with millions of tons of plastic produced, used, and discarded each year. This has created a colossal waste management challenge, and while recycling presents a solution, it is fraught with complexities. The key challenge lies in accurately identifying and sorting the diverse types of plastics. Traditional recycling methods often struggle to efficiently separate these materials, leading to contamination and diminished quality of recycled products. This inefficiency not only impacts the environment but also undermines the economic viability of recycling initiatives.

As the world grapples with this problem, the need for innovative solutions has never been more pressing. Effective recycling is not just about waste management; it’s about fundamentally changing our approach to resource usage and sustainability. This is where NIRLAB enters the picture, offering a groundbreaking solution poised to revolutionize plastic recycling.

Problem of Plastic Recycling

The heart of the plastic recycling challenge lies in the complexity and diversity of plastic materials. Plastics aren’t a single homogeneous substance; rather, they consist of various polymers, each with unique properties and recycling requirements. Mixing different types of plastics often results in phase separation and material degradation when melted together. Consequently, the quality of recycled products suffers, necessitating the addition of new materials to maintain product integrity.

Moreover, the identification of plastics within recycling facilities predominantly relies on manual, labor-intensive, and error-prone methods. This traditional approach is not just inefficient but also comes at a high economic and environmental cost. The limitations of current recycling technologies often result in a substantial portion of plastic waste being directed to landfills or incineration facilities. This, in turn, exacerbates environmental pollution and hinders sustainable waste management practices.

In this context, the urgent need for an efficient, accurate, and scalable technology for plastic identification and sorting becomes clear. Such a solution would not only enhance the effectiveness of recycling processes but also align with broader goals of environmental sustainability and the circular economy.

NIRLAB’s Solution:

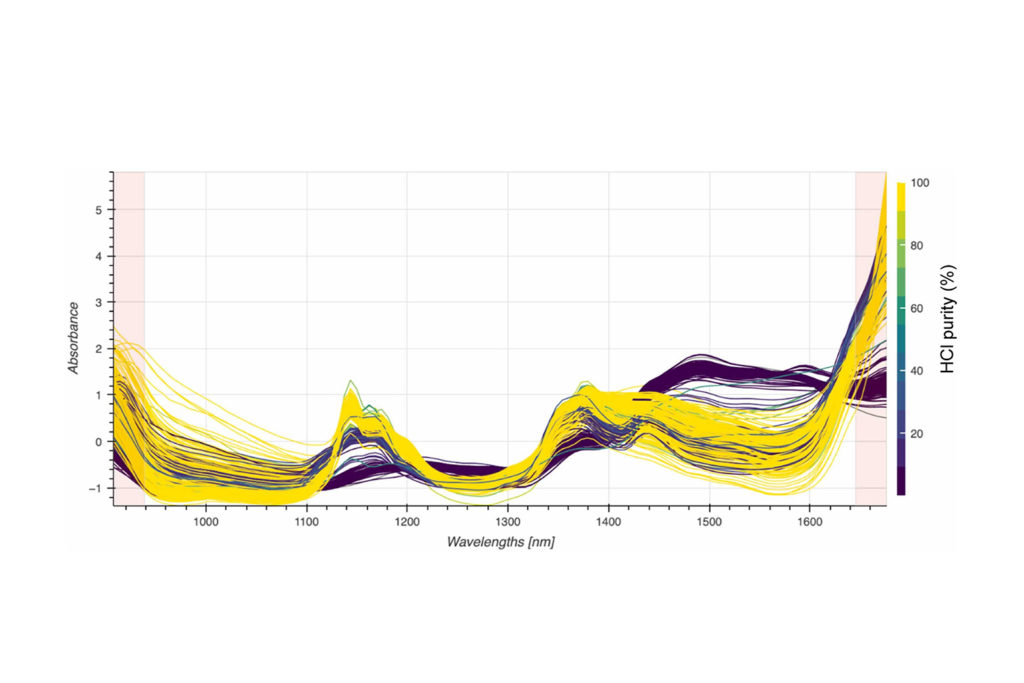

NIRLAB has developed an innovative solution that directly addresses the challenges faced in plastic recycling. Moreover, NIR reflectance spectroscopy, a powerful technology, distinguishes plastic packaging from waste based on their polymer type. NIR spectroscopy utilizes chemical signatures to distinguish and sort plastics like polyethylene, polypropylene, and polystyrene. It relies on the chemical makeup of polymer resins, such as PET, PVC, and Nylon, for effective sorting. NIR spectroscopy is key to distinguishing and sorting a wide range of plastics, contributing to efficient recycling. This identification process is not only accurate but also non-destructive, preserving the integrity of the samples.

NIRLAB has taken this technology a step further by creating an identification library algorithm. This software is capable of identifying up to 50 different plastic types. This includes the commonly referred to “big five” plastics: PE (HD and LD), PP, PS, PET, and PVC. This extensive library allows NIRLAB’s solution to handle a wide range of plastic materials, including colored, opaque, and transparent samples. Access the Polymer Solutions List here, and discover the versatility and precision that our technology has to offer.

Benefits of NIRLAB for Plastic Recycling:

NIRLAB’s NIRlight device, powered by NIR Spectroscopy, offers numerous advantages in the field of plastic recycling:

- Precise Identification: NIR Spectroscopy provides highly accurate identification of various plastic types, facilitating more effective sorting and reducing contamination.

- Speed and Efficiency: The NIRlight device delivers rapid results. Moreover, this significantly increases the speed of the recycling process and improving overall efficiency.

- Enhanced Sustainability: By improving sorting accuracy, NIR Spectroscopy contributes to more sustainable recycling practices. This by reducing the reliance on virgin materials and minimizing the environmental impact of recycling.

- Cost-Effectiveness: The enhanced efficiency and accuracy provided by NIR Spectroscopy can lead to cost savings for recycling facilities, making the recycling process more economically viable.

- Non-Invasive Technology: NIR Spectroscopy is a non-destructive testing method that preserves the integrity of samples, ensuring that the quality of the recycled materials remains high.

NIRLAB’s NIRlight device is designed with practicality in mind, featuring a wireless, compact, rugged, and ergonomic design for one-hand operation. It also includes a multifunction button for one-click data acquisition and an internal rechargeable Li battery with a runtime of over 10 hours. With IP65 and IP67 ratings, it is suitable for use in wet and dusty environments. Additionally, it is compatible with MicroNIR sampling accessories, making it a versatile tool for various applications.

NIRLAB offers the NIRLAB Suite, featuring Mobile and Web Apps for iOS and Android, enhancing user accessibility. With NIRLAB’s NIRlight device and NIR Spectroscopy, plastic recycling is poised for transformative change, benefiting the environment. The NIRLAB Suite, including Mobile and Web Apps for iOS and Android, elevates user experience and accessibility. NIRLAB’s NIRlight device, driven by NIR Spectroscopy, promises a transformative shift in plastic recycling for environmental sustainability.

Impact on the Recycling Industry:

NIRLAB’s NIRlight device represents more than just an incremental improvement; it signifies a transformative leap in the recycling industry. This innovative technology has the potential to redefine the very standards that govern plastic recycling, aligning them more closely with the principles of a circular economy. In doing so, NIRLAB is setting a new benchmark for how recycling operations can be optimized, revolutionizing the way we perceive and approach recycling challenges.

The scalable and practical nature of the NIRlight device empowers recycling facilities to streamline their processes, increase efficiency, and enhance the overall quality of recycled materials. With the ability to accurately identify and sort various plastic types, the recycling industry can significantly reduce contamination, conserve resources, and decrease its reliance on virgin materials. This has profound implications not only for the industry itself but for the broader environmental and economic landscape.

Conclusion

The integration of NIR Spectroscopy, exemplified by NIRLAB’s NIRlight device, represents a monumental advancement in the ongoing battle to address the complex challenges of plastic recycling. This transformative technology acts as a key that unlocks the full potential of sustainable recycling practices, offering a promising path toward a brighter future for environmental conservation.

NIRLAB’s commitment to innovation serves as a beacon of hope in the quest for a more sustainable and efficient recycling industry. Through the adoption of NIR Spectroscopy, the industry is poised to make substantial strides in reducing waste, conserving valuable resources, and minimizing its environmental footprint. NIRLAB’s visionary approach is not just a technological breakthrough; it is a catalyst for change, paving the way for a cleaner, greener planet and a more responsible and sustainable approach to managing our resources.

To delve further into the world of spectroscopy and discover the full capabilities of NIRLAB’s technology, we invite you to explore our other insightful articles, here. For personalized inquiries, reach out to us at contact@nirlab.com.

NIRLAB // Just Truth